How does a magnetic flow meter register water flow?

Magnetic flow sensors convert the velocity of a flowing fluid, waters for example, into a measurable electrical signal that is proportional to the flow rate.

Magnetic flow sensors convert the velocity of a flowing fluid, waters for example, into a measurable electrical signal that is proportional to the flow rate.

Usually magnetic flow meters have no moving parts or internal flow path obstructions, so they are easy to maintain.

Magnetic flow meters are typically specified to be the same size as the upstream and downstream piping, there is virtually no pressure loss through the flow meter, which can be very advantageous for some flow streams, like thicker slurries.

In our shop we have a few models (MVM-005-QA / MVM-001-Px / MVM-002-Px / MVM-030-Px) that have a narrowing slid in the piping to increase to flow-velocity this way we improved the accuracy of the meter.

Faraday's Law of Electromagnetic Induction

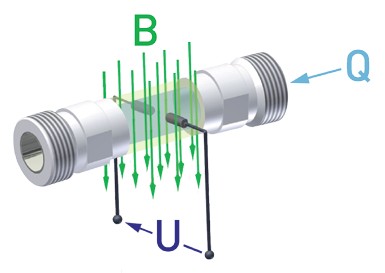

Fluid passes through the magnetic flow meter in a straight line through the piping of the sensor.

Fluid passes through the magnetic flow meter in a straight line through the piping of the sensor.

The cylindrical piping also allows a constant and directional magnetic field to be established across the diameter of the flow path.

The magic that creates the flow signal is based in the magnet!

The magnetic flow meter is surrounded by an iron-core, permanent magnet that creates a magnetic field to be established with lines of magnetic flux which pass vertically through the entire cross-section of the pipe and the flowing fluid.

The flowing fluid will pass through these lines of magnetic flux at a 90-degree angle or perpendicular to the lines of magnetic flux.

In 1831, Michael Faraday observed that a voltage is induced across any conductor as it moves at right angles through a magnetic field and that the voltage is proportional to the velocity of that conductor. This is called Faraday’s Law of Electromagnetic Induction.

Analog 4..20mA and Frequency output

To generate a voltage according to Faraday’s law, there must be moving conductor passing the magnetic field.

To generate a voltage according to Faraday’s law, there must be moving conductor passing the magnetic field.

That’s our flowing liquid (water), as the flowing fluid passes through the magnetic field at right-angles, according to Faraday’s Law, a voltage must be developed that is proportional to the fluid velocity.

The generated electric voltage is sensed by two leads, which are connected to the magnetic flow meter’s transmitter.

The transmitter converts the strength of the electrical signal into a volumetric flow rate (l/min)

and generates a 4 to 20 mA and/or frequency output to supply to a PLC, PAC or DAQ control system.

fluid CONDUCTIVITY what is the minimum?

The flowing fluid was the conductor, so the fluid must be conductive to work with a magnetic flow meter.

The flowing fluid was the conductor, so the fluid must be conductive to work with a magnetic flow meter.

What does it mean for a fluid to be conductive?

It means that the fluid must be able to conduct an electrical charge, thereby establishing a voltage that can be sensed by the mag meter’s electrodes.

The conductivity of liquids is measured in units of micro-Siemens-per-centimeter (μS/cm).

Our MAG-VIEW magnetic flow meters need an minimum of 20 or 50 μS/cm depending on the model.

| Liquid | Conductivity (μS/cm) |

|---|---|

Water | 200-800 |

Distilled water | 0-1 |

Latex paint | 700 |

Cola syrup | 600 |

Peanut butter | 0 |

Starch | 3000 |

Some fluids, such as seawater, have high conductivity a good fluid to measure with a magnetic flow meter.

Distilled water, on the other hand, has a very low conductivity, and cannot be measured with a magnetic flow meter.

Flow rates of vegetable and other oils, hydrocarbons, and most organic solutions cannot be measured with a magnetic flow meter.

In addition to seawater, flows of wastewater, and ionic solutions such as acids can easily be measured by magnetic flow meters.

How to select the right magnetic flow meter

When specifying magnetic flow meters, some important aspects must be considered in addition to the conductivity of the fluid, the expected minimum and maximum flow rate and is the fluid aggressive (acids).

When specifying magnetic flow meters, some important aspects must be considered in addition to the conductivity of the fluid, the expected minimum and maximum flow rate and is the fluid aggressive (acids).

Each model has a minimum and maximum flow rate that can be measured accurately.

If the pipe will not always be full of fluid, flow accuracy will be affected.

It might indicate the meter needs to be installed at a low point in the pipe or in an upwardly sloped pipe run to ensure a complete fill during operating conditions.

Another factor if the fluid corrosive or abrasive, with the material used in the flow meter.

Our MAG-VIEW instruments are mainly used with Stainless steel 1.4404 (AISI 316L), for more aggressive media that is not safe for stainless steel, Hastelloy C© is often used.

Our MVM-QA models have the option on request to have Hastelloy C© wetter parts for long durability.

For non-conductive liquids, you can use our liquid Vortex Flow meters. These meters utilize the vortex shedding principle, conductivity is not needed.