Magnetic Flow Meters for Direct-to-Chip Cooling in High-Performance AI Servers

🤖 Summarize this page with AI: 💬 ChatGPT

As artificial intelligence workloads continue to grow, high-performance chips such as the NVIDIA H100 and Blackwell architectures are pushing thermal limits with a thermal design power (TDP) of 700W or more. Effective cooling has become one of the most critical design factors for engineers in data center infrastructure and high-performance computing (HPC) systems.

Liquid cooling, especially direct-to-chip water cooling (D2C), is rapidly replacing traditional air-based solutions for AI hardware. However, maintaining the correct flow of cooling water through each component is just as crucial as the cooling method itself. This is where MAG-VIEW electromagnetic flow meters ensure precision, reliability, and peace of mind.

Maximum Efficiency – Liquid cooling removes heat up to 3,000 times more effectively than traditional air cooling.

Reduced Energy Costs – AI data centers save an average of 20–40% on energy by adopting liquid cooling.

Smaller Footprint – Fewer fans and less hardware mean data centers can operate in a more compact space.

Sustainable Solution – Liquid cooling consumes less water and significantly reduces carbon emissions.

Why Direct-to-Chip Cooling Matters in AI Data Centers

.png) In AI chip cooling systems, water flow rate directly impacts thermal performance and energy efficiency.

In AI chip cooling systems, water flow rate directly impacts thermal performance and energy efficiency.

Too little flow can cause dangerous hotspots and reduce chip lifespan. Too much flow wastes pumping energy and provides diminishing thermal returns.

Direct-to-chip cooling typically requires very low flows, often between 1 and 2 liters per minute for the cold plate, while the at rack level can reach up to 30 to 60 l/min. Even high-density racks' main supply lines may handle much higher flows up to 250 l/min to feed multiple racks or cooling manifolds.

Liquid cooling leverages the higher thermal transfer properties of water or other dielectric fluids to dissipate heat from server components efficiently. This solution is 3,000 times more effective than using air cooling alone for HPC infrastructure, whose heat levels outpace the capabilities of traditional methods. Liquid cooling includes various techniques for managing heat in artificial intelligence data centers.

Direct-to-chip (D2C) cooling, also known as cold plate cooling, is a sophisticated cooling method wherein a cold plate is mounted directly onto the chip (GPU or CPU). The plate facilitates the transfer of heat from the chip to a circulating coolant, which then dissipates heat

Direct-to-chip (D2C) cooling, also known as cold plate cooling, is a sophisticated cooling method wherein a cold plate is mounted directly onto the chip (GPU or CPU). The plate facilitates the transfer of heat from the chip to a circulating coolant, which then dissipates heat

The widespread adoption of HPC services, such as AI, machine learning (ML), and data analytics, causes a fast rise in chip, server, and rack densities and power consumption.

As rack densities rise to 20 kilowatts (kW) and quickly approach 50 kW, the heat levels of HPC infrastructure are pushing the capabilities of traditional room cooling methods to their limits. Moreover, there is increasing global pressure on data centers and other enterprises to continuously reduce power consumption. To meet these demands, data center operators are investigating their liquid cooling options

Per GPU cold plate: ~1–5 L/min.

Per 8-GPU server: ~30–40 L/min.

Per rack (50–200 kW load): ~70–300 L/min, depending on ΔT.

Why Is Data Centre Cooling Critical?

High temperature and humidity levels pose serious risks to IT infrastructure. Servers, CPUs, GPUs, and storage devices naturally generate heat during operation. Without effective cooling, this heat can lead to critical problems such as:

✔ Overheating: Continuous exposure to high temperatures may cause equipment failure.

✔ Component Damage: Excessive accelerates the wear and tear of sensitive electronics, shortening their lifespan.

✔ Operational Disruptions: Malfunctions can trigger costly downtime and even result in data loss.

✔ Safety Hazards: Heat accumulation increases the likelihood of electrical issues and fire risks.

By ensuring optimal temperature and humidity control, advanced cooling solutions improve data center reliability, extend hardware life, and maintain safe, uninterrupted performance.

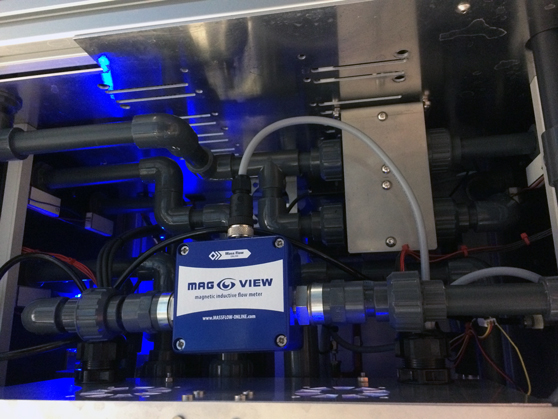

MAG-VIEW Electromagnetic Flow Meters: Designed for Data Center Cooling

Our MAG-VIEW flow meters are purpose-built to deliver accurate, maintenance-free flow measurement across an exceptionally wide range—from ultra-low flows to high-volume cooling loops.

| Model | Flow Range | Accuracy |

|---|---|---|

| MVM-001-PA | 0.0083 – 1 L/min | ±1% FS (<50% FS), ±2% FS (>50% FS) |

| MVM-002-PA | 0.05 – 2 L/min | ±1% FS (<50% FS), ±2% FS (>50% FS) |

| MVM-030-PA | 0.1 – 30 L/min | ±0.7% of reading ±0.3% of range |

| MVM-060-PA | 0.2 – 60 L/min | ±0.7% of reading ±0.3% of range |

| MVM-250-PA | 5 – 250 L/min | ±(1.5% of reading + 0.3% of range) |

Key Features Engineers Value

Electromagnetic measurement - no moving parts, no wear

Electromagnetic measurement - no moving parts, no wear- Low pressure drop, even at high flows

- Fast response time (<500 ms)

- Suitable for contaminated liquids

- Mountable in any position

- Free pipe cross-section for minimal flow disruption

- Durable stainless steel 1.4571 construction

- 16 bar pressure rating, -20…90°C temperature range

- Analog 4–20 mA and frequency outputs for easy integration

Applications in AI Cooling Systems

MAG-VIEW flow meters are used in multiple stages of liquid cooling systems:

- Main coolant supply lines to racks or cooling distribution units

- Direct-to-chip cooling circuits with ultra-low flows

- Cold plate cooling loops for GPUs and AI accelerators

- Compact systems where space is limited, thanks to flexible mounting

Why Engineers Choose MAG-VIEW

- Wide flow range, from 0.0083 L/min to 250 L/min, covering every cooling stage

- Immediate online availability from stock

- Precision measurement ensures stable chip temperatures and energy efficiency

- Compatible with both existing and new cooling installations

Ready to Optimize Your AI Cooling?

Whether you’re designing a cooling loop for high-density GPU racks or fine-tuning direct-to-chip water flow, MAG-VIEW flow meters offer the accuracy, durability, and flexibility you need.

MVM-P Series – starting at €535

MVM-P Series – starting at €535

- 5 models from 1 l/min up to 250 l/min

- Robust metal housing for high temperature and pressure

- Pressure rating: up to 16 bar

- Temperature: up to 90°C

- Frequency output and/or analogue output 4...20 mA

- For conductive liquids (≥50 μS/cm)

- Maintenance-free - no moving parts

Mass Flow Online Benefits

✅ Fast delivery from stock, shipment in 2 business days

✅ Made in the EU

✅ Online support available

✅ Secure payment via Credit Card, PayPal or Bank transfer

✅ Competitive prices