“Electric cables ensure connectivity all over the world.“

“Electric cables ensure connectivity all over the world.“

Production process

Cables are made of two basic parts: the conductor and the insulation. The conductor allows the flow of electrical flow in one or more directions. The insulation maintains the flow of electricity because very little electricity is able to flow through it under the power of an electric field. Most conductors in cables are made of copper or aluminum of which the diameter has to be reduced in a process called wire drawing to the required dimensions this increases ductility and conductivity. The production process from raw material to cable is as follows:

- The copper or aluminum arrives in 8mm rods that have to be drawn to the required size by heating up the material to draw it to the required size.

- The next step in the process is called wiring where conductors with different cross-sections are stranded together depending on the required capacity of the cable.

- Then the conductor is insulated with a cover to ensure that there are no leakages for this different materials like PVC, EPR and Teflon may be used depending on the characteristics of the cable.

- Phase wiring is the step where several wires are grouped together to create a multi-core cable, to identify the different phases the cables get different colors or numbers.

- To improve the cables further additional coverings can be added to insulate and protect the cables further, often these coverings are made of steel or aluminum.

- An outer sheath is added to protect the conductors and insulate them from external elements like rain and damaging during the installation of the cable.

- Throughout the process the cables are tested to check for and prevent leakages and test the overall quality.

What we offer

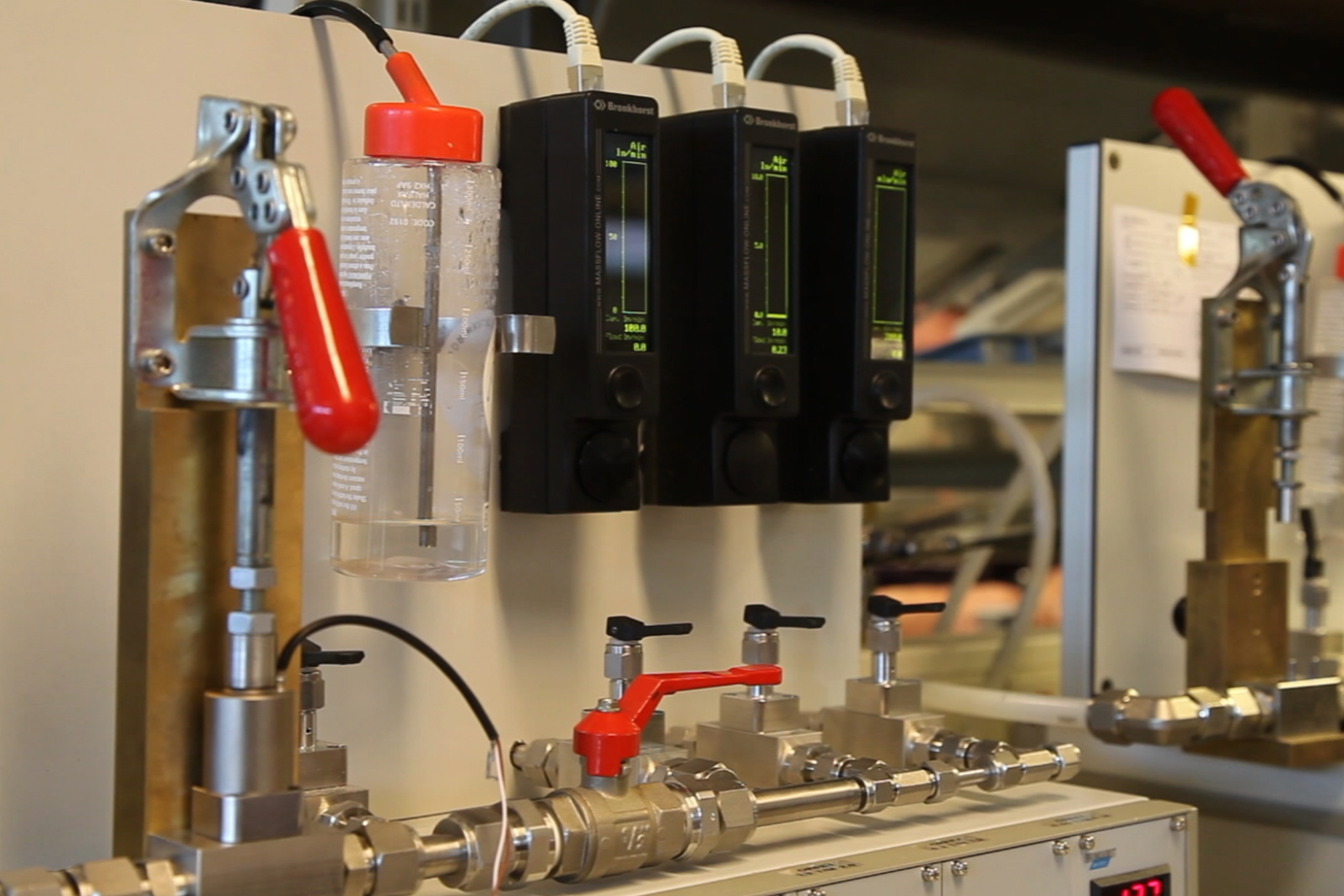

Mass Flow ONLINE offers MASS-VIEW Meters, Controllers and Regulators that can assist in this production of cables and wires. To be ensured of a high quality product the production process has to be monitored closely and materials have to be measured precisely. The MASS-VIEW allows for direct measurements, regulation and control over the process with a high accuracy and rangeability that is clearly displayed on its OLED display.

10 pre-installed gases for many possibilities, like Air, N2, O2, CO2, CO, N2O, Ar, CH4, C3H8 and C4H10.

- MASS-VIEW meters / regulators / controllers are available in wide flow ranges from 10 – 200 mln/min up to 1 – 500 ln/min.

- The compactness of the MASS-VIEW® allows to construct a portable and easy-to-use rig.

- Special designed MASS-VIEW models that is suited for H2 (Hydrogen) and He (Helium).