MS-106 MASS-STREAM 200 ln/min

- Proven direct inline CTA sensor (no bypass)

- Excellent repeatability

- Compact, rugged design (IP65, dust and waterproof)

- Very low pressure drop

- Less sensitivity to humidity or dirt

- With integrated multi-functional TFT display

Multiple gases

Multiple outputs

Pre-installed gases

| Gases | max. range |

|---|---|

| Air, N2,,O2 | 200 ln/min (= 200 SLM) |

| Ar | 400 ln/min (= 400 SLM) |

| CH4 | 120 ln/min (= 120 SLM) |

| CO2 | 215 ln/min (= 215 SLM) |

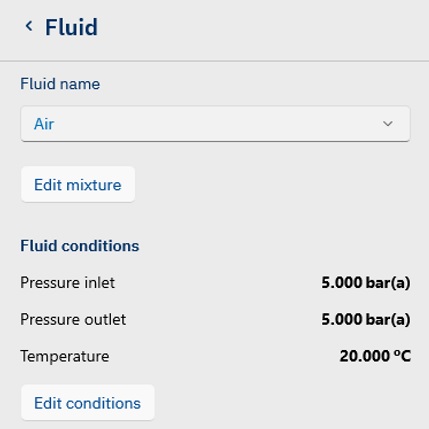

With free software Bronkhorst FlowSuite you can add one of the 34 available fluids or create mixtures on to the instrument.

This way you have a multi fluid instrument for your application

The instrument can be easily hooked up to a PC by using additional cables.

Read here how to hookup the MASS-STREAM to the PC

Features of MS-106 MASS-STREAM 200 ln/min

- Direct inline measurement principle

- Usable for virtually every kind of gas or gas-mix

- Mass flow measurement wide scope of applications

- Good response times

- Including calibration certificate

- Low sensitivity to dirt and humidity

- Compact and robust design

- Measurement without moving parts

- Connect the instrument to a PLC (programmable logic controller), PAC (programmable automation controllers) or DAQ (data acquisition system) with our loose end cable 7.03.191

- Modern multi-functional TFT display

- IP65 compliant

- Operator buttons on the instrument

- Customized adjustable multi-functional display: actual flow, totaliser with memory and reset,

alarm, setup and much more

Technical specifications

Measurement / control system

Flow range

up to 200ln/min Air

Accuracy

± 1,0 % RD plus ± 0.5% FS (at calibration conditions)

(incl. factory calibration certificate on Air)

(incl. factory calibration certificate on Air)

Repeatability

< 0,2 % FS

Turndown ratio

1:50

Operating pressure

up to 10 bar (g)

Pre-installed gases

Air, N2, O2, Ar, CH4, CO2 + FLUIDAT Onboard

Standard calibration gas

Air, other gases are converted using our FLUIDAT Onboard model which will introduce small inaccuracy

Response time (sensor)

approx. 0,9 sec.

Operating temperature

0 … 50 °C

Leak integrity, outboard

tested < 2 x 10-8 mbar l/s He

Attitude sensitivity

at 90° deviation from horizontal max. error 0,2 % at 1 bar typical N2

Pressure sensitivity

±0,3% Rd/bar typical (Air)

Temperature Sensitivity

±0,1% Rd/°C (Air)

Mechanical parts

Material (wetted parts)

Instrument body: Aluminium EN AW-6082-T6 Sieves, rings and sensor: Stainless steel SS 316

Process connections

BSPP female thread G1/2" (ISO1179-1)

Seals

FKM

Ingress protection

IP65

Storage / transport conditions

0 … 50 °C, max. 95% RH (non-condensing)

Electrical properties

Power supply

+15 … 24 Vdc ±10%

Analog output

4…20 mA sourcing output

EMC

CE / RoHS

Digital Communication

RS232

Electrical connection

8 DIN (male)

Downloads

Applications

- Calibration of air samplers

- Process gas measurement in food industry, chemical and petrochemical industries, in fermentation installations and in biotechnology

- 3D printing of metal products

- Gas consumption measurement for internal accounting

- Methane production in anaerobic digesters

- Oxygen supply in beer brewing process

- Surface treatment

- Test benches

- Aeration of liquids or substances

- Ratio control in burner & furnace applications

- And much more