Analog Flow Meter for Flow Measurement – In Stock & Easy to Order

Discover our high‑quality low flow meters—directly available online, without lengthy quotation procedures. At Mass Flow Online you can instantly select, compare, and buy your analog flow meters, whether you need a magnetic flow meter or a vortex flow meter. Choose the right instrument for your application and start measuring with precision as soon as tomorrow.

Discover our high‑quality low flow meters—directly available online, without lengthy quotation procedures. At Mass Flow Online you can instantly select, compare, and buy your analog flow meters, whether you need a magnetic flow meter or a vortex flow meter. Choose the right instrument for your application and start measuring with precision as soon as tomorrow.

• Pricing from €550 for the magnetic flow meter and €205 for the vortex flow meter

• Pressure ratings up to 10 bar or 16 bar

• Temperature capability up to 90°C or 125°C

• 4…20 mA analog output

• Suitable for conductive and non‑conductive liquids

• Very low pressure drop

🕒 Fast delivery from stock, shipment in 2 business days

🇪🇺 Made in the EU

💬 Online support available

💳 Secure payment via Credit Card, PayPal or Bank transfer

✅ Competitive prices

Buy analog flow meter: Speed, precision, and immediate results for your process

In modern industrial automation, reliable flow measurement is essential. Whether you're cooling high‑performance servers, dosing additives, or monitoring process water, a stable and accurate analog flow meter ensures process continuity and quality. At Massflow‑online.com you won’t wait weeks for quotes—you can instantly select and buy an analog flow meter directly from stock. Our meters provide robust 4–20 mA output, excellent noise immunity, and seamless integration with any PLC or SCADA system, making them the trusted choice for fast, reliable low‑flow measurement.

The power of simplicity: What is an analog flow meter?

When we speak of an analog flow meter in a modern industrial context, we rarely mean outdated mechanical dial meters. We are referring to advanced electronic meters (transmitters) that generate standardized analog output signals. The most common standards are the 4–20 mA current loop and the 0–10 V voltage output. This signal is linear and directly proportional to the measured flow: 4 mA (or 0 V) corresponds to zero flow, while 20 mA (or 10 V) corresponds to the full-scale value of the meter.

Why is an analog flow meter still the undisputed industry standard in a world that is rapidly digitizing with protocols like Modbus or IO-Link? The answer lies in robustness and simplicity. A 4–20 mA signal is extremely resistant to electrical noise and voltage-drop issues across long cable distances. If cable resistance increases, the current-loop transmitter compensates, ensuring the PLC receives an accurate value. Nearly every industrial controller—from a basic Arduino in a test setup to high-end Siemens or Allen-Bradley PLCs—can read this signal directly without complex drivers or communication configuration. It is plug-and-play at its purest.

Deep analysis: Applications of water flow meters

Water is undoubtedly the most frequently measured liquid in industry. The search for a buy analog flow meter water originates from the enormous variety of critical applications. It’s not simply "measuring water"; it’s about ensuring process stability and optimization.

High-Performance Computing and Data Centers

The explosive growth of Artificial Intelligence and cloud computing demands tremendous processing power. Modern server racks generate significant heat, which can no longer be removed efficiently using air cooling. Liquid cooling is becoming the new norm, where water (or water-glycol mixtures) circulates close to processors. Stable flow is crucial; if it drops, CPUs may throttle or become permanently damaged. Our Vortex flow meters, such as the LVB series, are perfect for this environment. They contain no moving parts—ideal for cleanroom maintenance—and deliver a stable analog output for Building Management Systems to control pumps.

Concrete Industry and Additives

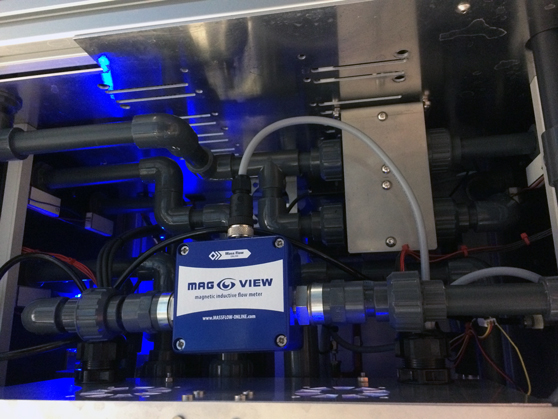

In the construction sector, the ratio of water and chemical additives (super-plasticizers) in concrete must be extremely precise. Too much water weakens the concrete (lower compressive strength); too little makes it unworkable. A reliable analog flow meter water ensures exact batch dosing. Our electromagnetic meters (MAG-VIEW or MVM series) are often used because they have a free bore, do not clog, and cause no pressure loss—essential for fast filling processes.

Agritech and Horticulture

In modern greenhouse farming, water management is directly tied to profitability. In hydroponic systems, plants must receive exact amounts of water and nutrients. An inline meter connected to the climate computer allows growers to control irrigation cycles with milliliter-level precision.

Inline measurement: Why inline installation is the standard

For most industrial processes and OEM machine-building, an inline solution is the only logical choice. When you search for buy inline analog flow meter, you are looking for a device that integrates seamlessly into your pipeline. Alternatives such as clamp-on ultrasonic meters can be convenient for temporary measurements, but they are more sensitive to vibrations, pipe wall irregularities, and acoustic coupling issues.

For most industrial processes and OEM machine-building, an inline solution is the only logical choice. When you search for buy inline analog flow meter, you are looking for a device that integrates seamlessly into your pipeline. Alternatives such as clamp-on ultrasonic meters can be convenient for temporary measurements, but they are more sensitive to vibrations, pipe wall irregularities, and acoustic coupling issues.

Inline meters measure the fluid directly—without interference from pipe walls—ensuring maximum accuracy and response time. At Massflow-online, we offer meters with standard industrial process connections such as BSP threads. Installation is fast, and the meter is factory-calibrated according to strict standards, ready for immediate use.

Technology comparison: Which types of flow meters exist?

We specialize in technologies that offer the best balance of price, accuracy, and reliability. The most relevant flow meter types for liquids in our assortment are Vortex and Electromagnetic, with Ultrasonic as an additional option.

1. Vortex Flow Meters (LIQUI-VIEW series)

These operate using the Kármán Vortex Street principle. A bluff body placed in the flow generates vortices proportional to flow velocity. A piezo-electric sensor detects these pressure fluctuations. Advantages: No moving parts, suitable for conductive and non-conductive liquids (such as demineralized water), excellent price-performance ratio. Note: Requires a minimum flow velocity to generate stable vortices; less suitable for very low flows.

2. Electromagnetic Flow Meters (MAG-VIEW)

These work according to Faraday’s law of induction. A conductive fluid flowing through a magnetic field generates a voltage proportional to flow velocity, measured by electrodes. Advantages: Completely free bore (no pressure loss), suitable for low-flow measurement, insensitive to viscosity, temperature, or density. Note: Liquid must be electrically conductive; unsuitable for ultrapure water or oil.

Massflow-online vs. traditional suppliers: A leap in efficiency

The industrial measurement market is traditionally dominated by major brands such as Krohne, Brooks Instrument, or Alicat. These suppliers deliver excellent equipment, especially for large-scale engineering projects in heavy industries. However, their business model often relies heavily on engineering-to-order, resulting in long quotation cycles and delivery times of 8–12 weeks.

Massflow-online.com operates differently. We position ourselves as the fast, efficient link in your supply chain. This means: Transparency: No "call for price"—you see prices and quantity breaks immediately in the webshop. Speed: Because we maintain stock of standard models, we typically ship within days. Order today, and your process can be running again this week. Quality: Fast delivery does not mean reduced quality. Our MAG-VIEW and LIQUI-VIEW series offer the same industrial robustness expected from A-brands—without the bureaucracy.

Buyer’s checklist: Ensure the perfect selection before you buy analog flow meter water

Before you decide to buy analog flow meter water, we recommend running through this checklist. It guarantees that the meter perfectly matches your process:

- Medium (Liquid): Is it water, oil, coolant, or a chemical? Check chemical compatibility of the wetted parts. For water, stainless steel is fine; for aggressive substances, Hastelloy or plastic is required.

- Conductivity: Is the liquid electrically conductive? Tap water and wastewater are conductive (suitable for MAG meters). Deionized water are insulating (choose Vortex Flow meter).

- Flow range: A flow meter is most accurate in the middle or top of its range. Don’t choose a meter that constantly runs at only 5% capacity; accuracy drops. A rule of thumb: your normal process flow should be about 50-70% of the meter’s range.

- Process conditions: What are the temperature and system pressure?

- Signal type: Do you need a 4-20mA signal for your PLC? Sometimes a pulse (frequency) signal is more useful if you just count totals. Our meters often offer both or are easily configurable.

Installation advice: Get the most out of your analog flow meter

Even the best meter performs poorly with bad installation. A crucial aspect of installing an analog flow meter is respecting inlet and outlet lengths. Fluid flow needs room to stabilize after a bend, pump or valve. Turbulence in the pipe disturbs the measurement.

As a rule of thumb: provide at least 10-15x pipe diameters of straight run before the meter and 10-15x diameters after. For a 10mm line this means 150mm straight pipe before the inlet. This ensures a laminar flow profile. Also note orientation: the line should always be full of liquid. Air bubbles ruin accuracy. Installing in an upward section is often preferred.

Frequently Asked Questions (FAQ)

- Which flow meter should I buy?

This primarily depends on the conductivity and purity of your liquid. For conductive water (dirty or clean) with no pressure loss: choose an electromagnetic meter (MAG-VIEW). For coolant water, deionized water or non-conductive liquids: choose a Vortex meter (LVB) . Always check that your desired flow falls within the meter’s range.

- Can I order a liquid flow meter directly?

Yes, that is the core strength of Massflow-online.com. Unlike traditional suppliers, you can configure, see the price and order online. We ship from stock.

- What exactly does a flow meter measure?

A flow meter measures the volume of liquid that passes through the pipe per unit of time (for example liters per minute). An analog meter translates this physical phenomenon into an electrical signal (e.g. 4-20 mA) that can be read by control systems.

- What is the difference between analog and digital in this context?

Modern meters operate digitally internally, but the term “analog” refers to the output to your system. A 4-20mA analog signal is the industry standard for robust, real-time process control without complex digital communication protocols.

- Flow meter water: what is it for?

It’s used to monitor consumption (cost savings), protect equipment (cooling water monitoring), and guarantee product quality (recipe dosing). It provides insight and control.

- Advice when purchasing flow meters: where do I start?

Start with the specifications of your liquid (conductivity, temperature) and your pipe (diameter, flow range). Contact our specialists for a quick check.

Conclusion: Your partner in process certainty

The search for the right measurement solution does not have to be complex. When your process calls for direct watertight control, and you search terms like analog flow meter water, reliability is your top priority. We give today’s engineer and buyer the tools to act immediately: no unnecessary waits, no hidden costs, but high-quality Vortex and electromagnetic meters that do what they are supposed to do. Whether you are an OEM builder looking for a reliable partner for series production, or an end user needing a defective meter replaced right away: we are here.