Buy Mag Meter for Liquid Measurement – MAG‑VIEW Electromagnetic Flow Meters

Mag meter the MAG‑VIEW™ use the inductive measuring principle, delivering high accuracy without moving parts. This makes them ideal for contaminated liquids, compact machines, and applications where traditional flow sensors fail. With no mechanical wear, no pressure drop, and reliable performance even in harsh conditions, MAG‑VIEW™ offers long‑life, interference‑free flow measurement.

Mag meter the MAG‑VIEW™ use the inductive measuring principle, delivering high accuracy without moving parts. This makes them ideal for contaminated liquids, compact machines, and applications where traditional flow sensors fail. With no mechanical wear, no pressure drop, and reliable performance even in harsh conditions, MAG‑VIEW™ offers long‑life, interference‑free flow measurement.

- 11 models, ranges starting from 0.0083 l/min up to 250 l/min

- Pricing starts at € 550,-

- Pressure rating: up to 10 bar and 16 bar

- Temperature: up to 90°C

- Frequency output and analogue output 4...20 mA

- For conductive liquids (≥20 μS/cm)

- Free cross section → Very low pressure drop

🕒 Fast delivery from stock, shipment in 2 business days

🇪🇺 Made in the EU

💬 Online support available

💳 Secure payment via Credit Card, PayPal or Bank transfer

✅ Competitive prices

Use the table to select the Mag meter that matches your flow

Flow Ranges | Metal version | Plastic version |

| 0.0083 .. 1 l/min | MVM-001-PA | |

| 0.05 .. 2 l/min | MVM-002-PA | |

| 0.1 .. 2 l/min | MVM-002-QA | |

| 0.25 .. 5 l/min | MVM-005-QA | |

| 1 .. 20 l/min | MVM-020-QA | |

| 0.1 .. 30 l/min | MVM-030-PA | |

| 2.5 .. 50 l/min | MVM-050-QA | |

| 0.2 .. 60 l/min | MVM-060-PA | |

| 5 .. 200 l/min | MVM-200-QA | |

| 12.5 .. 250 l/min | MVM-250-QA | |

| 5 .. 250 l/min | MVM-250-PA |

Accurate Flow Measurement Without Hassle: Why a MAG Meter Is the Industrial Standard

The ultimate guide to the mag meter flow meter: technology, purchasing and applications

In the dynamic world of the process industry, machine building and industrial automation, precision and reliability are not a luxury but a necessity. Whether you are responsible for monitoring cooling water circuits in a high-tech production facility, accurately dosing fertilizers in greenhouse horticulture, or building skids for chemical processing: your measuring instruments form the heart of your operation. If they fail, the process comes to a halt. And downtime costs money. A lot of money.

In the dynamic world of the process industry, machine building and industrial automation, precision and reliability are not a luxury but a necessity. Whether you are responsible for monitoring cooling water circuits in a high-tech production facility, accurately dosing fertilizers in greenhouse horticulture, or building skids for chemical processing: your measuring instruments form the heart of your operation. If they fail, the process comes to a halt. And downtime costs money. A lot of money.

If you are looking for a robust solution for measuring conductive liquids, you will almost immediately end up with the electromagnetic flow meter, better known as the MAG meter. At Massflow-online.com, we understand that engineers and buyers in today’s market do not have time for complex quotation processes or unclear delivery times. That is why we combine high-quality engineering with the efficiency of a modern online mag meter shop.

In this in-depth article, we dive deep into the world of electromagnetic flow measurement. We explain how the technology works, highlight critical specifications, discuss common installation pitfalls and show why the MAG-VIEW series is the smartest choice for your process.

What Is a Mag Meter Flow Meter and How Does the Technology Work?

A mag meter flow meter is an advanced instrument that measures the volumetric flow of liquids based on Faraday’s law of electromagnetic induction. Although the name sounds futuristic, the principle has been known since the 19th century and has proven to be extremely reliable.

A mag meter flow meter is an advanced instrument that measures the volumetric flow of liquids based on Faraday’s law of electromagnetic induction. Although the name sounds futuristic, the principle has been known since the 19th century and has proven to be extremely reliable.

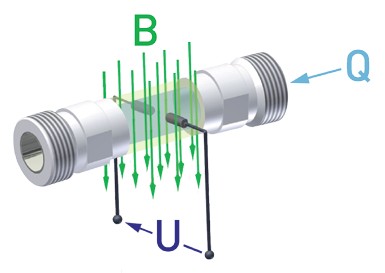

Here is how it works: a magnetic field is generated inside the measuring tube by electromagnetic coils. When an electrically conductive liquid flows through this magnetic field, the liquid itself acts as a moving conductor. According to Faraday’s law, this movement induces an electrical voltage perpendicular to both the flow direction and the magnetic field.

This induced voltage is detected by two electrodes mounted in the wall of the measuring tube. The key advantage of this system is its linearity: the measured voltage is directly proportional to the flow velocity of the liquid. Since the internal diameter of the tube is known, the electronics can accurately convert this signal into a precise volumetric flow rate, such as liters per minute.

Unlike mechanical flow meters (such as turbine, oval gear or positive displacement meters), a mag meter has no moving parts at all. There are no bearings that can seize, no impellers that can break, and no obstructions that could cause clogging. The meter features a full bore design, resulting in virtually no pressure loss. This means your pumps consume less energy and your system efficiency improves. In addition, this construction makes the meter virtually maintenance-free and extremely durable, even in continuous industrial operation.

The MAG-VIEW: Compact Powerhouse for Industrial Applications

Many traditional mag meters are designed for heavy infrastructure projects: large, heavy, expensive and complex to configure. For machine builders (OEMs) and process engineers looking for a compact solution, these meters are often overkill.

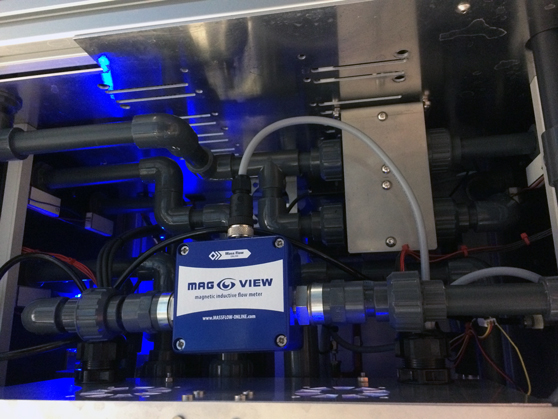

This is where the MAG-VIEW series from Massflow-online.com stands out. The MAG-VIEW range is specifically developed for applications where space is limited but performance is critical.

It is a compact and lightweight solution, yet robust enough for industrial environments, typically with an IP65 protection class. The housing protects advanced electronics that are equipped as standard with modern output signals, such as a 4–20 mA analog output for real-time monitoring and a frequency output for totalizing. Integration into a PLC or SCADA system is therefore straightforward.

Whether you need flow measurement for process control in the food and beverage industry, water treatment systems or mobile dosing units, the MAG-VIEW offers a wide turndown ratio and high accuracy, without the disadvantages of mechanical wear.

Essential Selection Criteria: What to Consider When You Buy a MAG Meter

Selecting the right flow meter is critical for process reliability. A wrong choice can lead to measurement errors, system failures or even equipment damage. To ensure your decision to buy mag meter technology is the right one, we recommend checking the following factors step by step.

1. Liquid Conductivity

This is the most important requirement. An electromagnetic flow meter works only with electrically conductive liquids. Compact models like the MAG-VIEW typically require a minimum conductivity between 20 and 50 µS/cm.

Drinking water, acids, bases, fertilizers and slurries usually have sufficient conductivity. However, demineralized water, ultra-pure water and oils or fats are not conductive. If in doubt, a simple rule applies: if the medium is water-based and not extremely purified, a mag meter will usually work. For non-conductive fluids, alternative technologies such vortex flow meters are required.

2. Flow Range and Diameter

Do not automatically match the meter diameter to the pipe diameter. Flow velocity is what matters. A mag meter performs best when the operating flow is not at the extreme low end of its measuring range. Ideally, your nominal flow should be located in the middle or upper part of the meter’s range. Our datasheets clearly show minimum and maximum flow rates per model.

3. Process Pressure and Temperature

Always verify that the maximum pressure and temperature of your application are within the meter’s limits. The MAG-VIEW series typically supports liquid temperatures up to 60°C or 90°C (depending on electronics configuration) and pressures up to 16 bar (PN16). This covers approximately 90% of standard industrial and water-based applications.

4. Chemical Compatibility of Wetted Parts

The wetted parts are critical. These include the liner of the measuring tube and the electrodes that come into direct contact with the fluid. Our mag meters typically use stainless steel 316L electrodes and tube. These materials offer excellent resistance to a wide range of chemicals, although highly aggressive media should always be checked against a chemical resistance chart.

The MAG-VIEW has stainless steel models, plastic models and Hastelloy for agressive acids.

Why You Should Buy a MAG Meter Online Now

In traditional industry, the procurement of instrumentation is often a slow process. You request a quote, wait three days, receive a price with a delivery time of six to eight weeks, and then still have to negotiate. There are times when you simply don’t have that time. Perhaps a critical production line is down due to a faulty meter, or a prototype machine must be presented to a customer next week. The decision to buy a mag meter through Massflow-online.com is a strategic choice for speed, transparency, and certainty.

In traditional industry, the procurement of instrumentation is often a slow process. You request a quote, wait three days, receive a price with a delivery time of six to eight weeks, and then still have to negotiate. There are times when you simply don’t have that time. Perhaps a critical production line is down due to a faulty meter, or a prototype machine must be presented to a customer next week. The decision to buy a mag meter through Massflow-online.com is a strategic choice for speed, transparency, and certainty.

Unlike traditional suppliers, who often work on a 'make-to-order' basis, we use a stock-holding model focused on the business market. We see ourselves as the logistical extension of your technical service or purchasing department. The benefits of our approach are clear:

- Immediate availability: No production waiting times. What is in stock is shipped immediately. Often, you receive the meter within 1 to 2 business days within the Benelux, and quickly beyond.

- No technical risk due to proven design: Because there are no moving parts, there is less wear and tear. This means less downtime and lower operational expenses (OPEX) throughout the meter’s lifespan.

- Insensitive to contamination: Because there are no obstructions in the pipe, dirt particles, sand, or fibers simply flow through. This is ideal for slurries, wastewater, or cooling water that is not perfectly filtered.

MAG Meter Price: Transparent and Fair

One of the biggest frustrations in B2B purchasing is the lack of price transparency. “Price on request” often means uncertainty. At Massflow-online.com, we take a different approach. The mag meter price is clearly visible on the product page.

The MAG-VIEW series is competitively priced, with entry-level models starting at € 550,- (excluding VAT). This transparency allows you to calculate project costs, budgets and maintenance expenses without surprises.

Compared to large brands such as Krohne, Endress+Hauser or Yokogawa, the MAG-VIEW offers a fit-for-purpose solution without paying for unnecessary features, oversized designs or long delivery times.

Applications: From Water Management to Factory Automation

MAG meters are versatile and suitable for a wide range of liquid measurement applications. Typical use cases include cooling water monitoring, water treatment systems, chemical dosing skids and smart factory automation.

Thanks to the full bore design, compact dimensions and reliable outputs, the MAG-VIEW integrates seamlessly into modern industrial environments and supports real-time data acquisition for process optimization and preventive maintenance.

Comparision: Why choose for MAG-VIEW

When comparing the MAG-VIEW to alternative measurement principles and competitors, the benefits for the user quickly become clear. Let's first look at the measurement principle. Compared to mechanical meters (such as turbine meters), the mag meter wins in terms of longevity and reliability. A turbine meter has moving parts that wear out, especially if there is dirt in the water. A mag meter does not have this problem and maintains its accuracy over a much longer period.

Compared to ultrasonic clamp-on meters, the mag meter is often more accurate and stable, especially at lower flows, and is usually more cost-effective for pipe diameters up to 2 inches. Ultrasonic meters are great for temporary measurements, but for permanent installations, a mag meter (in-line) offers a more robust connection to the process.

Looking at the landscape of suppliers, we see top brands like Krohne, Yokogawa, or Endress+Hauser. These are fantastic companies that provide instruments for the most extreme conditions (think oil refineries, hazardous explosion zones, or temperatures of 200°C). However, for most standard industrial applications in machine building (OEM), these meters are often over-engineered, too large, very expensive, and come with long delivery times. Massflow-online.com fills precisely this gap: we offer the specifications you truly need for 90% of applications, but then immediately deliverable and affordable. We provide no unnecessary complexity, just pure functionality.

Insatllation tipsfor optimal performance

Although mag meters are very forgiving, accuracy depends on proper installation. A common mistake is having too short an inlet and outlet. For a stable flow profile, the fluid needs some time to 'settle' before passing the sensor. We generally recommend a straight pipe length of at least 10 times the diameter before the meter, and 5times the diameter after the meter. Avoid placing the meter immediately after a bend or valve if you want to achieve the highest accuracy.

Frequently Asked Questions About MAG Meters

What are typical MAG meter specifications?

MAG-VIEW meters typically offer an accuracy between ±1% and ±2% of reading, support pressures up to 16 bar, temperatures up to 90°C and provide standard outputs such as 4–20 mA, pulse or frequency signals with a 24 V DC power supply.

What is the best flow meter for my application?

If your liquid is conductive and you require low maintenance, a mag meter is usually the best choice. For non-conductive liquids such as oils or demineralized water, alternative technologies are required.

Need a liquid flow meter fast?

Our mag meter shop shows real-time stock availability. Orders placed on business days are often processed the same day, minimizing downtime.

How much does a MAG meter cost?

Prices typically start around € 550,- for compact models and increase with diameter and flow range. Even so, mag meters remain far more cost-effective than Coriolis meters or heavy-duty project-based electromagnetic flow meters.

Conclusion: Your Partner in Efficient Flow Measurement

Whether you are an OEM looking for a reliable series flow meter or a process operator in urgent need of a replacement, Massflow-online.com is your trusted partner. With the MAG-VIEW series, you get a high-quality mag meter flow meter that combines accuracy, durability and ease of installation.

We simplify industrial purchasing with transparent mag meter prices, clear specifications, downloadable documentation and a user-friendly mag meter shop. Ready to optimize your process? Compare models and buy mag meter solutions directly online. Your flow is our focus.